Secondary Tempering

Single Fluid Heat Transfer Temperature Control System

Temperature range -120℃~300℃

Using on-site thermal energy: Steam, Cooling water or Ultra-low temperature liquid

Control the reaction process temperature and material temperature

Temperature Process Control Principle (Controlling the temperature of the material in the reactor):

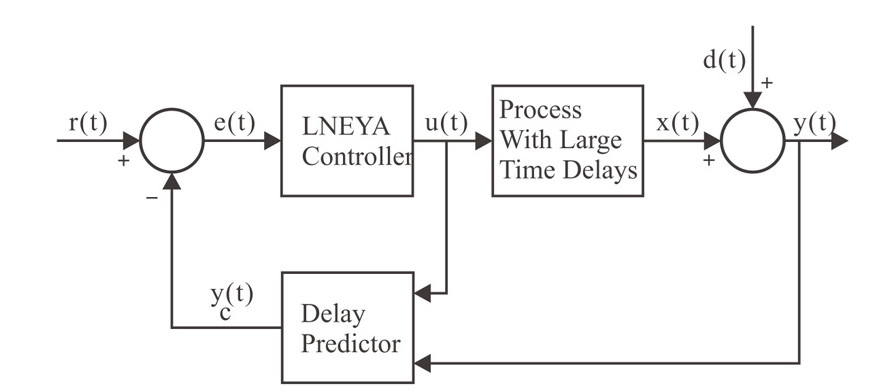

Through three-point sampling (material temperature point, temperature control system outlet temperature, temperature control system inlet temperature), through our company’s self created model free self building tree algorithm and general anti lag cascade algorithm.

Product Description:

Integrate into a single-fluid system or secondary loop that controls the temperature of process equipment using existing thermal energy (eg, steam, cooling water, and ultra-low temperature liquids—“primary systems”) infrastructure. This completes the flow of only one heat transfer liquid into the jacket of the reaction vessel (rather than direct steam, cooling water or ultra-low temperature liquid). The temperature of the whole reaction process is controlled by operation.

- Details

ST 10℃~135℃

- 尺寸138×81×58 cm(长×宽×高)

ST 10℃~135℃ PRODUCT ADVANTAGES · Material Temperature Control Accuracy ±1.0℃ · Heating Power 25kW~300kW · Circulation Pump 110L/min 2.5bar~600L/min 2.5bar · Power 1.8kW~7.5kW · Steam Pressure 4~6bar …

- Details

SR -120℃~+250℃

- 尺寸138×81×58 cm(长×宽×高)

SR -120℃~+250℃ PRODUCT ADVANTAGES · Material Temperature Control Accuracy ±1.0℃ · Heating Power 25kW~80kW · Circulation Pump 200L/min 2.5bar~750L/min 2.5bar · Power 2.30kW~10.5kW · Temperature Control Reactant tempe…

- Details

ZLF -45℃~+250℃

- 尺寸138×81×58 cm(长×宽×高)

ZLF -45℃~+250℃ PRODUCT ADVANTAGES · Material Temperature Control Accuracy ±1.0℃ · Heating Power 25kW~80kW · Circulation Pump 150L/min 2.5bar~750L/min 2.5bar · Power 2.30kW~10.5kW · Temperature Control Reactant tempe…

loading…

已经是到最后一篇内容了!

Advantages of using a single fluid heat transfer temperature control system:

A. Users can get a closed and repeatable temperature control in a wide temperature range, which can realize temperature control from -120 degrees to 300 degrees;

B. Avoid the replacement of traditional equipment and facilities and the need for jacket maintenance; the smaller fluid volume also ensures the rapid response of the control loop and the thermal response delay is small;

C. Built-in electric heating and heat transfer oil auxiliary system, which can automatically turn on the auxiliary heating system according to the demand, and reduce the pressure of steam use;

D. It can achieve the purpose of saving energy through fast operation and accurate matching of each heat demand;

E. Control the temperature of the entire reaction process through accurate and fast calculations, and perform rapid response control for exothermic and endothermic reactions in the entire reaction process;

F. Standardized interfaces are reserved, and cold and heat source heat exchange modules can be added according to actual needs;

G. You can choose to control the temperature of the reaction process and the temperature of the single fluid, and the temperature difference between the temperature of the reaction process and the temperature of the heat conduction single fluid can be set and controlled;

H. Formula management and production process records can be carried out.

DCS Integrated Temperature Control System

Realize the automation and serialization of pharmaceutical production

Through the application of advanced pharmaceutical equipment and its automatic control technology, the technical level of the product has been improved, the product quality and output have been greatly improved, and the market competitiveness of the product has been improved.

Customization of TCU Reactor Temperature Control Solutions

Please contact us : maira@lneya.com

Other Recommended Products

Recirculating Chiller

Temperature Range -5℃~50℃

Used for Cooling of heating part of semiconductor manufacturing device; the heating part of the laser device; the heating part of the analysis and detection machine…

More Details

Air-cooled Chillers

Temperature Range -80℃~30℃

Used for reactor material temperature control, Exothermic reaction in biopharmaceutical process

More Details

Water-cooled Chillers

Temperature Range -110℃~-5℃

Used for Supply of pharmaceutical, biochemical, freeze-drying, petrochemical and other cold sources

More Details

Vehicle Test Chillers

Temperature Range -40℃~100℃

Used for vehicle quality test: battery life test, fuel injector/motor test bench, airbag test, component test bench, etc.

More Details

Semiconductor Test Chillers

Temperature Range -85℃~250℃

Used for Test package cooling and heating in chip semiconductor industry…

More Details LNEYA Thermal Test Chillers

LNEYA Thermal Test Chillers